Types of timber beam weakness that can be repaired

1. Bending/deflection - caused by overloading, undersized timber section, poor quality timber, insect or rot damage

2. Change of Use - from domestic to commercial, added loading such as: storage, filing, piano, Museum

3. New Build - need for lowest height of timber to preserve headroom, loft conversion, ring beams, ridge boards, joists

4. Breakage - partial or complete failure

Total failure due to severe insect attack. Excessive deflection, overloaded. Ridge beam parts for Loft Conversion.

Go Direct to Timber Repair Order Page

Examples of Beam repairs - weakness caused by insect attack and rot

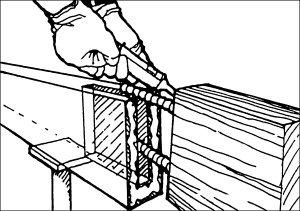

Timber Beams that have partly broken or been eaten by Rot or Wood Boring Insects can be repaired using High Tensile Steel Bars, Zinc Plated Allthread, or Epoxy-Glass Bars or Stainless Steel Bars. The bars are then embedded in Structural Epoxy Pouring Resin or Grout.

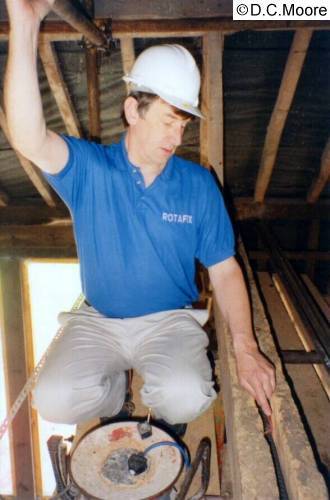

New timber component in place - note bars in slots - ready for resin pouring or injection..

Independent Engineering calculation service available from us, from £350 per beam, Indemnified (Insured)

Go Direct to Timber Repair Order Page

How to increase strength

Upgrade the Beam or Joist - cut a slot, or slots, along the length to within about 40mm of the base and bond in BS4449 High Tensile Rebar with Structural Epoxy Pouring Grout. This is know as a 'modified flitch' design and approximately doubles the stiffness of a typical timber, in bend.

Barn, Somerset - overloaded tie beams in a barn now carrying heavy clay tiles on the roof (had been a thatched roof and then was converted to a lightweight galvanized sheet roof).

Go Direct to Timber Repair Order Page

Examples of beam strength upgrading using bars and resins

Loft Conversion, Newton Abbot - maximum ridge board to be 12" x 4" (300mm x 100mm), not strong enough to meet Engineers specification.

For more Technical Information and a Photo Gallery go to:www.timber.org.uk

Beam upgrade with reconnection of joists

Go Direct to Timber Repair Order Page

How to extend ends that have rotted

Cut out the decay and either:

1. Cut off the end completely and fit a Timber-Resin Splice, priced and manufactured to fit the exact size and timber type.

2. Build a box around the missing part, fit Rebars to extend into the sound part and fill with Structural Epoxy Pouring Grout.

Theory and Practice - Timber-Resin Splice top slot (Type C) joist end repair in place

Go Direct to Timber Repair Order Page

Examples of extending rotted beam ends using bars and resins

Bindon House Hotel, Somerset - truss ends and tie beams, Dry and Wet Rot. The ends were replaced using TYPE E Timber-Resin Splice units, made to measure .

Timber-Resin Splices and bars in place.

For more Technical Information and a Photo Gallery go to:www.timber.org.uk

Go Direct to Timber Repair Order Page

Order Pages

Repairs | Beams | Privacy Policy | Returns Policy

Contact | About Us | About the Author

Property Repair Systems

T: 01626 872886

E: Mail us help@propertyrepairsystems.co.uk

Other Property Repair Systems Sites:

www.drywallandfloor.co.uk - membranes for lining damp walls, floors, basements and cellars

www.epoxy-info.co.uk - epoxy resins for repairing wood, concrete, brick and stone

www.fire-door-paint.co.uk - upgrade doors to 30 minutes fire resistance

www.joist-repair.co.uk - how to quickly repair joists and beams of any size

www.propertyrepairsystems.co.uk - our Home Site

www.steel-fire-paint.co.uk - treat steel with Intumescent Paint to provide fire protection

www.timber.org.uk - systems of repair, with step by step methods

Site written by: David Moore

David Moore, B.A. (Hons.), C.T.I.S., C.R.D.S. Technical Author

Google+